Table of Contents

Main Bearings in Engine

There is a saying, “Everything rotates on bearing except the Earth.” Amidst the symphony of pistons, crankshafts, and cylinders, there’s a silent yet indispensable hero: the main bearings. These unassuming components dwell deep within your engine’s block, bearing the hefty responsibility of supporting the Crankshaft, preserving exact alignment, and tirelessly battling friction. In this article, we will discuss the Main bearings and their failures.

Think of an engine as a grand orchestra, each part harmonizing to generate the mechanical symphony that propels your Vessel. The Crankshaft, serving as the orchestra conductor, orchestrates the synchronized motion of pistons, converting fuel into the driving force of your Marine Engine.

Yet, their duty surpasses mere support. Main bearings also assume the responsibility of preserving precise alignment, akin to a misaligned gear in a clock that disrupts its timekeeping. Any misalignment in the engine could spell disaster. The main bearings keep the Crankshaft perfectly in place inside the machine. The perfect positioning of the Crankshaft keeps damage that might be costly to repair at bay while facilitating the smooth operation of all the engine’s components.

Also, these simple parts help lessen the rubbing inside the engine. Rubbing is like the enemy of efficiency; it takes away power and makes extra heat. Main bearings incorporate meticulously crafted layers of sleek, low-friction materials, often composed of diverse metals and alloys.

Classifications of Bearings on Ships Based on Functions

There are many different types of bearings on the market today. Many folks know about the regular ball bearing, but other bearings are used for different things. One type of bearing is the lead bronze bearing.

Lead bronze bearings are made of a special alloy that contains lead and copper. Due to this composition, a bearing becomes solid and durable to undertake any load transmitted by a crankshaft. Lead bronze bearings are often used in high-load applications that must withstand a lot of wear and tear. Another type of bearing is the bi-metal bearing.

Bi-metal bearings are made from two different types of metal, usually steel and copper. The steel backing of the bearing provides bearing strength and durability, while copper helps reduce the friction even to some extent in the boundary lubrication conditions.

What is the classification of bearings?

Main Bearing: Main bearings are critical components in marine engines, supporting the crankshaft. They are built to endure large weights and guarantee the crankshaft rotates smoothly.

Top End Bearing (Cross Head / Gudgeon Pin Bearing): These bearings are located at the upper End of the connecting rod, connecting to the piston’s crosshead or gudgeon pin. They facilitate the reciprocating motion of the piston.

Bottom End Bearing (Crank Pin Bearing): Positioned at the lower End of the connecting rod, these bearings support the crankshaft’s crankpin. They help convert the reciprocating motion of the piston into rotary motion.

Thrust Pad Bearing: Thrust pad bearings are essential for managing axial loads in marine propulsion systems. They prevent excessive axial movement of the crankshaft, ensuring its stability during operation.

Pedestal Bearing (Generator Alternator Side Insulated Bearing): Pedestal bearings are used in electrical generators and ship alternators. These special parts help hold things that spin; sometimes, they have special covering to stop electricity from going through them.

These different kinds of parts are essential for ensuring ships work well. They do specific jobs to keep ship engines and other machines running smoothly. Each type of part is made just right to handle its job in the complicated machinery of a ship.

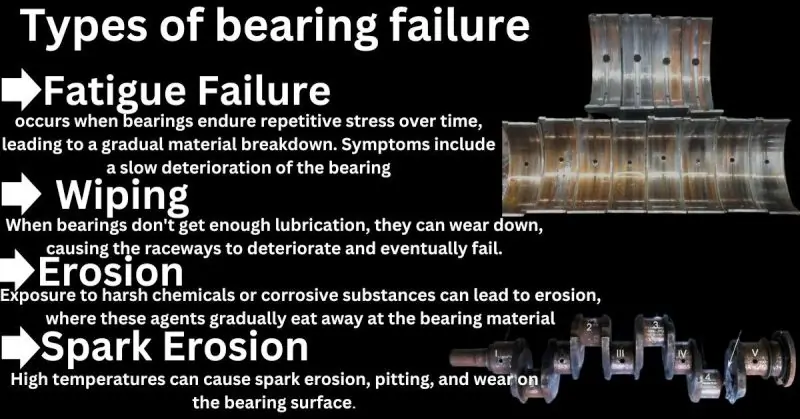

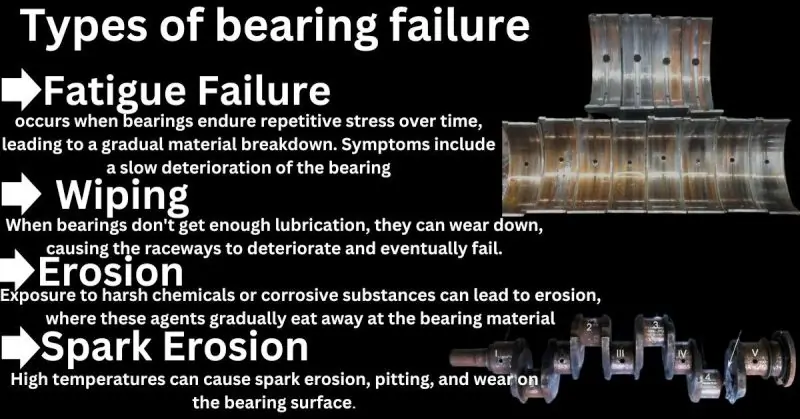

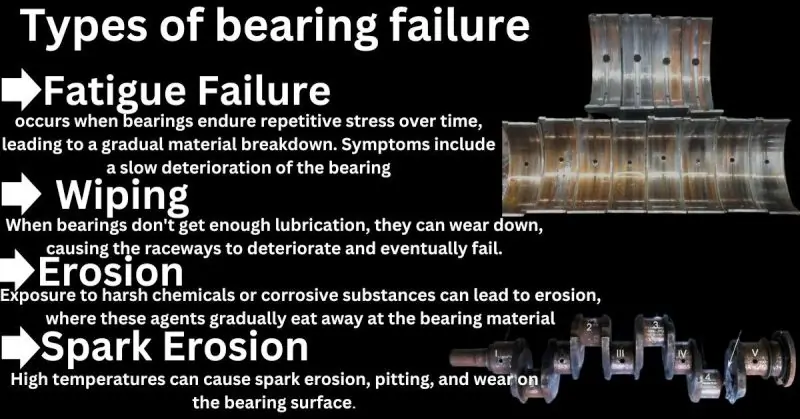

Types of bearing failure

Bearing failures can happen for various reasons, and each type has its causes and signs. Here are some common types of bearing failures:

- Fatigue Failure occurs when bearings endure repetitive stress over time, leading to a gradual material breakdown. Symptoms include a slow deterioration of the bearing.

- Wiping: When bearings don’t get enough lubrication, they can wear down, causing the raceways to deteriorate and eventually fail.

- Erosion: Exposure to harsh chemicals or corrosive substances can lead to erosion, where these agents gradually eat away at the bearing material.

- Spark Erosion: High temperatures can cause spark erosion, pitting, and wear on the bearing surface.

During maintenance, it’s essential to use new bearings according to the manufacturer’s recommendations. However, an inspection may indicate the need for premature bearing replacement. Examining used bearings can help uncover the underlying causes of deterioration.

In most cases, all bearings will exhibit signs of wear during a close inspection. These signs may include scoring, wiping, dirt accumulation, or foreign particles embedded in the bearing. Additionally, any damage or uneven wear in one or more crankshafts can indicate other underlying issues that need attention. Proper maintenance and timely replacement of bearings are crucial to ensure machinery’s smooth operation and longevity.

Understanding Bearing Material Properties

Bearing materials play a crucial role in making sure bearings work effectively. They need to have specific qualities to do their job right. Here’s a breakdown of the essential properties they should have:

1. Conformability: Bearing materials must be able to “flex” under pressure without harming the more challenging steel parts. Think of it like a cushion that can handle heavy weights without breaking.

2. Corrosion Resistance: Bearings must put up with oils and other stuff that can damage them over time. So, they need to be corrosion-resistant, like having a protective shield.

3. Compatibility: The bearing material should align well with the surface it rubs against. It’s like having two friends who work well together; they shouldn’t fight.

4. Anti-Weld and Anti-Score Properties: These are like safety features. They prevent damage when the bearing starts or stops, like a car with good brakes.

5. Antifriction and Wear Properties: Imagine a smoothly rolling ball – that’s what this property is about. Bearings need to move without rubbing too much, which helps them last a long time and work well.

Different Bearing Materials

White Metal

- Composition: Tin (Sn) + Antimony (Sb) + Copper (Cu)

- Applications: Thin-walled bearings for stiff crosshead assembly (88% Sn + 8% Sb + 4% Cu), Thick-walled bearings for flexible crosshead and bottom end bearing (87% Sn + 9% Sb + 4% Cu)

- Characteristics: Tin provides a soft matrix for misalignment, Antimony forms hard cubes for load resistance (tends to segregate during casting), and Copper evenly disperses Antimony and solidifies first.

Copper Lead & Lead Bronze

- Composition: Copper Lead (Brass – Cu + Zn) & Lead Bronze (Cu + Sn)

- Load Capacity: Can withstand three times higher load than white metal.

- Structure: Copper/Bronze matrix provides strength, Lead remains free, and steel strips offer backing.

- Overlay: Typically 0.024 – 0.04 mm thickness of lead-tin or lead-tin-copper for initial running.

- Characteristics: Resistant to acid attack, lower embeddability & conformability, effective running-in phase.

Aluminum Tin

- Composition: Aluminum (Al) Matrix + Silicon (Si) minor content + Overlay (Pb+Sn) + Steel Backing

- Performance: Offers three times the load-carrying capacity compared to white metal.

- Matrix: Soft aluminum matrix provides embeddability & conformability.

- Tin: Suspended tin particles provide bearing properties.

- Overlay: Typically 0.02 mm thickness of lead-tin for initial running.

- Requirements: Requires a hardened journal, resistant to acid attack, fatigue strength similar to Copper and lead.

These bearing materials serve specific purposes and offer different advantages based on load-bearing capacity, corrosion resistance, and other factors. The choice of bearing material depends on the specific requirements and operating conditions of the machinery used.

Types of Main Bearings

Lead Bronze Bearing: The Solution for Tough Conditions

When it comes to demanding conditions, finding a top-notch bearing that can handle the heat is essential. Enter our lead bronze bearing, a robust choice designed to excel in challenging environments.

This bearing boasts a four-layer composition, each serving a specific purpose:

Flash Layer: The outermost layer acts as a shield, safeguarding the bearing from corrosion and dust. It’s your first line of defense against the elements.

Nickel Barrier: Just beneath the flash layer, the nickel barrier is crucial in preventing tin from seeping into the bearing metal. This barrier helps maintain the integrity of the bearing.

Lead Bronze: The lead bronze layer is the heart of this bearing, serving as the primary bearing material. It’s the workhorse of the assembly, providing excellent anti-seizing properties, which means reduced friction and improved performance.

Steel Back: The final layer is the steel back, offering durability and strength to the bearing structure. It guarantees that the bearing can resist rigorous use and challenging circumstances.

Lead bronze bearing is a dependable option that fulfills your needs and goes above and beyond to exceed them.

Bi-metal Bearing: Durability Meets Performance

When finding a resilient and robust bearing, your search ends with a bi-metal bearing. The design of Bi-metal bearings withstands demanding applications and is strong and durable.

The construction of our bi-metal bearing consists of three distinct layers, each playing a vital role in its exceptional performance:

Aluminium Tin Layer: At the core of this bearing is the substantial and durable aluminum tin layer. The main part of this layer does the heavy lifting, holding up under lots of pressure and stress. Its toughness shows how stable the bearing is.

Bonding Layer: The bonding layer, which ensures the structural integrity of the bearing, securely joins the steel back and the top aluminum tin layer. This robust bond is crucial for maintaining the bearing’s overall sturdiness and long-term performance.

Steel Back: The steel back is the foundation of the bi-metal bearing, providing the necessary structural support and stability. This layer ensures the bearing can withstand the forces and wear associated with its application.

This bi-metal bearing is excellent for many jobs requiring something solid and long-lasting. Whether dealing with heavy stuff, lots of pressure, or challenging situations, this bearing is built to do a good job every time. It’s got three layers that make it difficult and dependable, so it’s a smart choice for even the most challenging mechanical tasks.

Tri-Metal Bearing: Excellence in Versatility

Introducing the Tri-Metal Bearing, a top-notch solution suitable for diverse applications. This really good bearing is designed to work well and last long. You can depend upon this bearing for various demanding situations.

Here’s a breakdown of what makes the Tri-Metal Bearing stand out:

Flash Layer: The top layer is a protective shield, safeguarding the bearing from corrosion and dust when not operating. This layer ensures that your bearing remains in top condition even during downtime.

Overlay (White Metal): The overlay is white metal, known for its remarkable durability. This sturdy layer forms the core of the bearing, providing the strength needed to withstand demanding conditions.

Interlay (Anti-Corrosive Layer): Sitting beneath the overlay, the interlay serves as an additional line of defense against wear and tear. It shields the bearing from the corrosive forces that can lead to premature deterioration.

Lining Layer (Friction Resistance): Nestled between the interlay and the steel back, the lining layer offers superior resistance to friction. Due to this feature, a bearing can handle high-speed applications at different loads.

The Tri-Metal Bearing is ideal for those seeking a versatile and dependable bearing that can excel in diverse settings. Don’t miss out on the opportunity to enhance your machinery’s performance—order your Tri-Metal Bearing today and experience the difference in quality and reliability.

What is a Thin Shell Bearing

A thin shell bearing refers to a bearing with specific characteristics related to its dimensions and installation:

- Wall Thickness to Diameter Ratio: The wall thickness to diameter ratio of a thin shell bearing varies based on the shaft diameter. For example, it may be 0.05 mm for a 40 mm shaft diameter and 0.02 mm for a 400 mm shaft diameter.

- Interference Fit or Bearing Crush: Thin shell bearings typically have an interference fit or bearing crush. This means they are designed to fit tightly onto the shaft, creating resistance to relative movement and preventing fretting.

- Axial Location: While thin shell bearings are designed for the correct axial location of the shell, they are not primarily intended to resist motion. They are often recessed below the bearing joint face.

- Installation: Thin shell bearings are typically installed with a free spread technique, where the bearing shell is snapped into the bearing housing. This method holds the bearing securely, even when the assembly is inverted during installation.

In summary, thin shell bearings are characterized by their specific wall thickness to diameter ratios, interference fit, and axial location features. They are designed to provide stability and prevent motion-related issues in machinery applications.

Advantages of Thin Shell Bearings

Thin shell bearings are more popular than conventional bearings due to their advantages.

High Load Carrying Capacity: These shell bearings can carry heavier loads, 5 times more than the conventional bearings.

Uniform Wall Thickness: These bearings feature a uniform wall thickness, allowing for better metallurgical control during white metal casting.

High Bond Strength: Thin shell bearings exhibit high bond strength between their layers. This bond strength is often assessed using ultrasonic testing methods, providing accurate and dependable results. This ensures the integrity and longevity of the bearing.

Reduced Thickness: Compared to conventional bearings, thin shell bearings have reduced thickness and lack keying grooves. This design choice enhances their fatigue strength, making them more resistant to wear and tear over time.

Reduced Blistering: Thin shell bearings are less prone to blistering on their bearing surface due to hydrogen gas emission. This reduced blistering contributes to the overall reliability and longevity of the bearings.

Differences Between Conventional and Thin Shell Bearings

Conventional Bearings:

Material Composition: Conventional bearings are typically constructed from forged steel, with a white metal lining on their running faces.

Vertical Clearance Adjustment: Vertical clearance in conventional bearings is achieved through shims.

Replacement Difficulty: Replacing conventional bearings can be challenging and often necessitates remodeling.

Handling and Storage: Conventional bearings are less convenient to handle, transport, and store.

Oil Groove Design: The careful design of oil grooves is required for adequate lubrication.

Load Capacity: Conventional bearings generally have a lower load-carrying capacity.

Manufacturing Costs: The manufacturing of conventional bearings tends to be costlier.

Thin Shell Bearings:

Material Composition: Thin shell bearings are tri-metal materials featuring a steel shell, a copper or lead alloy layer, and a thin surface layer of soft metal.

Replacement Ease: Replacing thin shell bearings is straightforward and does not require re-metalling.

Vertical Clearance Adjustment: Thin shell bearings do not rely on shims for vertical clearance adjustment.

Handling and Storage: These bearings are easier to handle, transport, and store, especially as spare parts.

Load Capacity: Thin shell bearings typically offer a higher load-carrying capacity.

Manufacturing Costs: They are more cost-effective to manufacture.

Lead Reading Not Required: There is no need for lead reading during maintenance or replacement.

Factors Impacting Bearing Operation

Bearing operation isn’t a simple affair; it’s influenced by many factors that have a big say in how well it works. Understanding how these factors come into play is crucial for keeping bearings running smoothly.

Operating Temperature: One of the big players is temperature. If a bearing operates at high temperatures, it tends to wear out faster and might not last as long. Conversely, running at low temperatures can make bearings complex and fragile, reducing their performance. Picking the suitable bearing for the specific temperature conditions is vital.

Working Temperature: This factor ties closely with the previous one. The temperature where the bearing does its job has a big say in how it’s lubricated. When things get too hot or cold, it can mess up the lubrication process, causing problems for the bearing.

Minimum Oil Film Thickness: This is like how much lubrication a bearing needs to stay happy. If there’s not enough oil, the bearing can start to wear down quickly, and that’s not good news for its performance or lifespan.

Rate of Oil Flow: How fast the oil moves through the bearing matters, too. If it’s too slow, the bearing might need more lubrication. If it’s too fast, it can cause excessive heat and wear.

Rate of Heat Production: Some bearings can get pretty hot when they work. The speed at which they produce heat affects how they perform and how long they last.

Power Loss of Bearing: This factor is about how much energy the bearing uses up while doing its job. Minimizing power loss is essential to keep things efficient.

So, when it comes to bearing operation, it’s not just about putting the suitable bearing in place; it’s also about understanding and managing these factors to ensure smooth and efficient performance.

Causes of Bearing Failure

When bearings fail, it’s often during their hard work under a load, suddenly coming to a stop. Many factors can lead to this, and understanding them is crucial. The primary culprit behind bearing failures is usually lubrication – precisely when the grease inside the bearing wears out. It’s essential to use the right amount of grease before doing it. To prevent premature bearing failures, Here’s a breakdown of the main causes of bearing failures:

- Dirt: Dirt, especially at the back of the bearing, can spell trouble.

- Inadequate Lube Oil: Insufficient lubrication can lead to problems. Ensuring that the lubrication system works correctly and doesn’t leak is vital.

- Wrong Assembly: Sometimes, bearings are put together the wrong way, like installing them backward or reversing connecting rod bearing caps.

- Components Machined Improperly: If parts like housing fillet radius or journals must be adequately machined, it can cause issues. They should be the right shape and size.

- Misalignment of Housing and Shaft: When the housing and shaft aren’t aligned correctly, it can distort the line bore of the housing, leading to trouble.

- Overloading: Too much load on the bearing can cause it to fail.

- Corrosion: Exposure to corrosive substances can damage the bearing over time.

- Cavitations: This occurs when tiny bubbles in a liquid repeatedly collapse near the bearing, causing damage.

Preventing bearing failure involves regular maintenance, using the correct lubrication, and ensuring proper assembly. By addressing these factors, you can extend the life of your bearings and keep your machinery running smoothly.

Bearing Installation Guidelines

Before you install engine bearings, there are some essential things to check and prepare:

Housing Bore: Make sure the place where the bearing goes, called the housing bore, is the right size, shape, and smoothness. It shouldn’t have any rough or uneven spots.

Pin: Check the part called the pin, which the bearing wraps around. It should be the correct size shape and should not have any cracks or sharp edges around the oil hole.

Alignment: Make sure the housing bore is in line and the holes where the connecting rods go are parallel.

Cleaning: Clean everything well. Dirt is a big reason why bearings can fail. It’s not enough to clean the outside of the engine. You also need to clean all the inside parts, like the filter housing, oil pump, oil pump screen, oil pan, and the channels inside the engine block where oil flows. You can use special cleaning machines or do it carefully by hand.

Prepare New Bearings: When you get new bearings, they often have a protective layer of oil or grease. Before you put them in, dip them in clean petroleum ether or turpentine. Then, use a soft brush to remove the protective layer. Be gentle, and don’t wipe the part that touches other parts.

Remember, bearings are exact parts, so handle them carefully to ensure they work well.

Blog Conclusion

We sincerely hope that you enjoyed reading about the main bearings! Our guide can help you make the best decision if you’re looking for new bearings for your engine. These pointers will help you get your machine back to working smoothly. Do not hesitate to contact us if you have any questions or comments.

We’d be delighted to hear from you! Feel free to visit us at https://marinediesel.co.in/ anytime.

You have brought up a very superb points, appreciate it for the post.

very nice publish, i certainly love this website, keep on it

sony music would be the biggest company in entertainment from what i see in the future. they have a good business plan-

Du er da godt nok hårdt ramt af spam kommentarer

A powerful share, I simply given this onto a colleague who was doing a bit of analysis on this. And he the truth is purchased me breakfast as a result of I found it for him.. smile. So let me reword that: Thnx for the treat! However yeah Thnkx for spending the time to debate this, I really feel strongly about it and love reading more on this topic. If potential, as you change into expertise, would you mind updating your weblog with more particulars? It’s extremely useful for me. Big thumb up for this weblog post!

How are You? I have been searching for great doing Web Design Glasgow, do You know any? See You!

Vouêtes vraiment bien informé et très intelligent. Vous avez écrit quelque chose que les gens puissent comprendre et faire l’objet fascinant pour tout le monde. Je suis sauver ce pour une utilisation future.

you’re really a good webmaster. The web site loading speed is incredible. It seems that you are doing any unique trick. Also, The contents are masterpiece. you’ve done a wonderful job on this topic!

You completed a few fine points there. I did a search on the subject and found nearly all persons will go along with with your blog.

Everyone loves what you guys are up too. This sort of clever work and exposure!

Keep up the wonderful works guys I’ve included you guys to

our blogroll.

It’s going to be ending of mine day, however before end I am

reading this fantastic article to increase my know-how.

I think that everything posted made a ton of sense. But, what about this?

what if you added a little content? I am not saying your

information isn’t good, however what if you added something that makes people want more?

I mean Main Bearings In Engine: 10 Surefire Tips To Prevent Failure is a little vanilla.

You might glance at Yahoo’s front page and watch how they write article headlines to grab people interested.

You might try adding a video or a picture or two to grab readers excited about what you’ve written. In my opinion,

it might make your blog a little bit more interesting.

I and also my friends appeared to be looking through the excellent tips and tricks from your web page and so quickly I had an awful suspicion I never thanked the blog owner for those techniques. All the young men had been as a consequence very interested to study them and already have without a doubt been taking advantage of those things. Appreciate your getting well helpful as well as for deciding upon some excellent subject areas millions of individuals are really wanting to be informed on. My honest apologies for not expressing gratitude to sooner.

Howdy exceptional website! Does running a blog similar to

this take a massive amount work? I’ve virtually no knowledge of computer programming however I had been hoping to start my own blog soon. Anyways,

should you have any ideas or tips for new blog owners please share.

I understand this is off topic nevertheless I simply had to ask.

Cheers!

Your blog has the same post as another author but i like your better.*:~;’

Good web site you have here.. It’s hard to find quality writing like yours these days.

I seriously appreciate individuals like you!

Take care!!

I am glad that it turned out so well and I hope it will continue in the .future because it is so worthwhile and meaningful to the community.

Hello to every body, it’s my first go to see of this web

site; this blog carries remarkable and in fact excellent material in support of visitors.

There’s noticeably a bundle to learn about this. I assume you made sure nice points in features also.

It’s remarkable to go to see this web page and reading the views of

all mates concerning this paragraph, while I am also eager of getting experience.

Rattling clean web site , regards for this post.

I just love to read new topics from you blog.,*-’-