Table of Contents

What are the 20 Reasons for Reduced Ship Auxiliary Engine Power

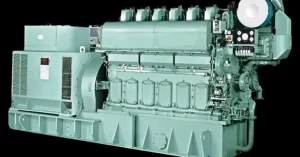

The performance of a ship’s auxiliary engine is essential for a continuous power supply on board. A sudden blackout due to any malfunction in the auxiliary engine can cause significant disruption in operations and have devastating consequences for the ship’s and its crew’s safety. Hence, it is essential to identify any reduction in the performance of the auxiliary engine due to wear and tear or other factors as early as possible.

A wise marine engineer always runs the minimum number of generators and looks for the maximum load. Not only does this give the auxiliary engine goodwill, but it also reduces overall fuel consumption and harmful emissions.

Lower engine performance results in higher exhaust temperatures, lower peak pressures, and lower performance. When the power of one generator degrades, another generator must be run in parallel to supplement the power demand.

Marine engineers need to be aware of possible causes that can lead to power loss from auxiliary engines.

In this article, we explore the various factors that can lead to a reduction in the performance of a ship’s auxiliary engine and how such situations can be avoided. Every ship has an auxiliary engine that operates on diesel or heavy fuel oil and helps power the ship when no onboard power generation is available.

Below are 20 possible causes of reduced power and performance of auxiliary engines installed on ships.

Too low Fuel Oil pressure

Fuel oil pressure less than the required specification can cause serious engine problems. Too low fuel oil pressure could be due to a bad fuel oil pump or fuel oil viscosity. If you find that your fuel oil pressure is low, it is essential to take steps to fix the problem before it causes further damage.

Grade of Fuel used

As for the type of fuel burned, fuel oil pressure plays a significant role in determining the fuel used. Fuel oil pressure is reduced by changing the grade from HFO (Heavy Fuel Oil) to MDO (Marine Diesel Oil), MGO (Marine Gas Oil), or LSFO (Low Sulphur Fuel Oil). This drop in fuel oil pressure means reduced engine power and efficiency. Additionally, it is essential to note that burning different fuel types can affect emissions and air quality. Therefore, it is necessary to choose the right fuel for your engine and avoid polluting the environment.

Fuel leak from the fuel injection system

The fuel injection system is an essential engine component responsible for supplying fuel. If the fuel pump parts are worn out, such as the plunger and barrels, it will cause a fuel leak, resulting in a drop in fuel pressure at the delivery point. This fuel leakage can lead to other problems, such as poor engine performance, increased emissions, and poor fuel economy. Therefore, it is essential to check your fuel system regularly to ensure that all components are working correctly and that there are no signs of wear or leaks.

Fuel Temperature

Fuel temperature is an essential factor in the performance of any engine. Excessive fuel temperature can reduce fuel viscosity and adversely affect fuel pressure. High fuel oil temperature can cause the engine to run inefficiently, losing power and efficiency. Keeping the fuel temperature within acceptable limits is important to ensure optimum engine performance. Fuel temperature depends on the type of fuel used in the engine.

Peak Pressure Difference

The peak pressure differentials between individual cylinders are one of the essential factors in determining overall engine performance. Differences in ignition pressure between cylinders can reduce power, torque, and fuel consumption. It can also cause misfires and increased emissions. Maintaining uniform ignition pressure across all cylinders is critical to ensuring optimal performance. Balancing of Peak pressure in the cylinder is achieved by using quality parts, performing regular maintenance checks, and dynamic engine tuning after the maintenance.

Chocked Fuel Filter

The fuel filter plays a vital role in the performance of your fuel oil system. A blocked or dirty fuel filter can cause a decrease in oil pressure, resulting in reduced performance and even engine failure. It is, therefore, essential to regularly check the fuel filter and replace it when necessary. The fuel filter is installed in the fuel system before the engine and, at times, can be easily accessed through an access panel. A fuel filter is a screen or strainer that filters the fuel as it enters the engine, preventing particles from clogging up the injection system.

Improper valve clearance

Improper valve clearance can have severe consequences for the engine. It can lead to decreased performance and excessive wear on internal components. The clearance between the intake/ exhaust valve and its guides is essential. If the clearance is more than required, it can increase friction between the parts, resulting in increased fuel consumption, higher emissions, and inefficient power output. Further damage may include burnt or stuck valves due to carbon build-up caused by improper combustion or valve clearance. Therefore, regular maintenance should be carried out to ensure no excessive gap between the valves and their guides, which could cause severe damage to the engine.

Damaged Exhaust Valve

A damaged exhaust valve or seat can be a severe issue for any engine. If the valve or seat is not sealing properly, it can cause a blow-by of exhaust gasses on combustion and increase the amount of unburned fuel released into the environment. A damaged exhaust valve or seat will increase emissions and decrease fuel efficiency. In addition, it can also cause engine misfires and other performance issues. Identifying and repairing a damaged exhaust valve or seat as soon as possible is essential to prevent further damage to the engine and ensure optimal performance.

High Exhaust Back Pressure

High exhaust back pressure is a common problem many Engines face, caused by a flaw in the exhaust piping installation or the silencer becoming fouled. High exhaust back pressure can lead to increased engine stress, lower fuel efficiency, and increased emissions. It is identifying the root cause of the problem before implementing necessary repairs. To tackle this issue, It is also essential to regularly check for signs of high backpressures, such as noisy engine performance or black smoke from the exhaust system. High backpressure can lead to poor fuel efficiency and increased emissions despite the promise of reduced engine stress.

Fouled exhaust Passages

An engine’s fouled exhaust passages can significantly cause decreased performance and increased fuel consumption. If a contaminated exhaust manifold is present, it can lead to a hindrance in the exhaust gas flow and an increase in the temperature of the exhaust. This issue must be addressed quickly, as it can severely affect engine performance and fuel efficiency. Knowing how to identify and combat this problem is essential for Marine Engineers.

Inadequate supply of fresh air

An adequate supply of fresh air is essential for efficient combustion in any process. Without the right amount of fresh air, there will be a reduction in the scavenged air supply, which can lead to an imbalance in the combustion process. Inadequate air supply means that fuel and energy efficiency will not only be reduced, but it can also lead to potential health hazards. Therefore, it is essential to ensure a sufficient supply of fresh air.

High intake air temperature to T/C

When a ship sails in particularly hot regions, the atmospheric air sucked in by the turbocharger will be much higher than usual. This results in high intake air temperature to the Turbocharger (T/C). To maintain efficiency, the T/C must operate at lower temperatures.

One way of doing this is by periodically cleaning the intake air cooler between the turbocharger and its intake manifold. A clean Intercooler and intake manifold can help reduce the incoming air’s temperature and prevent it from entering the T/C at too high temperatures for it to handle. Additionally, proper maintenance must be carried out regularly to ensure that all components work correctly and that no overheating occurs due to poor maintenance or weather conditions.

Too Low Charge Air Pressure

The charge air pressure of an engine is a critical factor in ensuring the machine’s optimal performance. If the scavenge air pressure is too low, it can cause many issues with combustion and cause a decrease in performance. The insufficient amount of air required for combustion would not reach each cylinder, resulting in poor fuel efficiency, clogged filters, and misfiring. Low scavenge air pressure can also lead to increased wear and tear on the engine components due to improper combustion processes.

It is essential to ensure that the charge air pressure is kept at a suitable level for optimal performance to prevent these issues from occurring. Appropriate charging pressure can be done by regularly checking the scavenge air pressure levels and making necessary adjustments.

High Charge Air temperature

With the development of automotive technology, it has become increasingly important to understand how high-charge air temperature affects engine performance. The cooler thermostat is the main factor in deciding the temperature of the output air supplied to the engine. If this setting is too high, the air temperature will increase significantly, leading to decreased engine performance and fuel consumption. Appropriate measures must be taken to reduce or manage high-charge air temperatures To ensure optimal performance and fuel efficiency.

Dirty Intercooler

A dirty intercooler is a severe problem that can negatively impact an engine’s performance. When seawater is used to cool the air, it needs to pass through an intercooler that should be kept clean and free of contaminants. If the intercooler is contaminated or dirty, it will not be able to allow enough seawater to properly cool the air before it enters the engine, leading to an increase in exhaust temperatures and reduced fuel efficiency.

Supply of intercoolers with high seawater temperature

The increasing seawater temperature is a significant challenge for the supply of intercoolers. If the seawater temperature is higher, the air cooled in the cooler will be warmer than usual, adversely affecting its performance. High charge temperature due to hot seawater can lead to a decrease in the efficiency and reliability of the system.

The Sea Water bypass from the air cooler is open.

The air coolers with an S.W. bypass valve are designed to control the cooling medium, i.e., seawater. If the bypass is open more than required, it can lead to inefficient system cooling and even damage the machine components due to excessive heat. Therefore, operators must ensure that the S.W. bypass from the air cooler is appropriately closed and not left open for too long.

Worn/damaged Compressor wheel, turbine, or nozzle ring

Worn or damaged compressor wheels, turbines, and nozzle rings are significant turbocharger issues. If these parts become fouled or damaged, it can obstruct the exhaust gas passage or decrease the amount of fresh air fed into the turbine. Fresh air starvation can drastically reduce performance and efficiency. Additionally, there is an increased risk of turbocharger failure due to excessive heat and pressure build-up. To prevent this from occurring, it is essential to regularly inspect these parts and replace any that have become worn or damaged.

Leakage in Scavenge Air

Leakage of scavenging air from the inlet pipe to the cylinder can be a significant problem for an engine. Incomplete combustion will occur due to less air supply, which can reduce the engine power output, increase fuel consumption, and cause other dangerous problems. Leakage of scavenge air should be detected and repaired at the earliest opportunity to maintain the optimum performance of an engine and prevent potential damage.

Improper tappet clearance adjustment

Setting the tappet clearance is an essential step in adjusting an engine. If the tappet clearance is set improperly, it can lead to various issues with your engine’s performance. Improper tappet clearance adjustment can cause problems from inefficient fuel consumption to an engine misfire.

Incorrectly adjusted tappet clearances will allow either inlet or exhaust valves to open more or less than required, resulting in too little or too much air entering and exiting the cylinders. Wrong tappet clearance can lead to poor combustion, low power output, increased fuel consumption, and increased emissions and noise levels.

You must adjust the tappet clearance accurately to ensure your engine runs at its optimal performance level. Failure to do so will result in costly repairs; therefore, you must take extra care when adjusting this part of your engine.

What fuel does a ship’s auxiliary engine use?

What type of fuel powers a ship’s auxiliary engine? Each ship has an auxiliary engine primarily running on diesel or heavy fuel oil. This engine powers the ship whenever it lacks onboard power generation.

Understanding the fuel choice for a ship’s auxiliary engine is pivotal for efficient ship operations.

Diesel, being relatively cleaner, often becomes the preferred choice for many modern vessels, especially when considering environmental regulations and emissions targets. On the other hand, although denser and sometimes less refined, heavy fuel oil offers economic advantages due to its cost-effectiveness, especially for large ships with high fuel consumption rates.

The choice of fuel can influence various factors onboard. For instance, diesel can lead to fewer engine deposits, potentially reducing maintenance intervals and costs. However, the cost savings from using heavy fuel oil might offset these maintenance benefits.

Furthermore, as the maritime industry moves towards a more sustainable future, the push for cleaner fuels and alternative energy sources grows stronger. This shift might influence the types of fuel auxiliary engines used in the coming years, with an increased emphasis on sustainability and reduced environmental impact.

FAQ on “Ship Auxiliary Engine Power”

Q1: What is the main role of the ship’s auxiliary engine?

A1 supplies power to essential systems and equipment beyond the main propulsion.

Q2: Why is consistent auxiliary engine power crucial on a ship?

A2: It ensures the uninterrupted operation of vital systems like lighting, communications, and cooling.

Q3: How often should the auxiliary engine be serviced?

A3: Regular maintenance is essential based on manufacturer guidelines and operational hours.

Q4: What happens if the auxiliary engine power fails?

A4: Critical systems may malfunction, jeopardizing safety and operations on the ship.

Blog Conclusion

In the intricate orchestra of a ship’s machinery, the auxiliary engine plays a pivotal, albeit often overlooked, role. This unsung champion ensures that beyond the ship’s primary propulsion, all other essential systems have the power to function seamlessly. The auxiliary engine powers lighting, communication devices, cooling systems, and other critical equipment that create a harmonious and safe maritime environment. As we delve deeper into the maritime world’s nuances, we recognize that the auxiliary engine isn’t just about power; it’s about consistency, reliability, and the unwavering promise of safety in the vast and unpredictable embrace of the oceans.

As shipping evolves, with technological advancements and an increasing emphasis on sustainability, the importance of efficient and reliable auxiliary power becomes even more pronounced. Concluding our exploration, it becomes clear that the auxiliary engine is a testament to human engineering ingenuity. It ensures that amidst the challenges of the deep blue, ships remain self-sufficient islands of power and capability, ready to face the horizons of tomorrow.