Table of Contents

Marine Air Compressor

Introduction

In this post on Best Tutorial on Marine Air Compressor,We will discuss the following topics

- What is a compressor,

- Uses of main Air Compressor on Board a ship,

- Compressor working principles,

- The general problem in compressors,

- How does a compressor work?

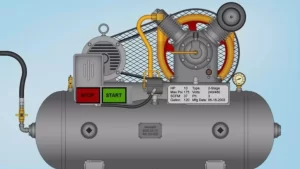

What is Air Compressor?

An Air compressor is a machine to increase the pressure. by compressing from low pressure to higher pressure by utilizing. some external source of energy.Electric motor or Diesel Engine drives the compressor

Classification of compressed air

- Main Air

- Instrument Air

Main Air: – (11 to 30 bar)

- Use of main air is for starting the main and auxiliary engines onboard a ship

- For supercharging purpose the engines

- For the operation of Lambda controller to boos the air at the change of loads in the engine.

Instrument Air; – (7 bars)

Use of Instrument air

1. Control system for several controls and automation.

2. Service air and control air application

3. Paint and spray instruments

4.Pneumatic hand tools

5. For machine cleaning

6. For Hydrophore ( A system to maintain the water pressure)

Important terminology used for compressor

Compression Ratio; – Ratio of volume pre- compression to the volume of air. post- compression is compression ratio.

Compressor Capacity; – Absolute volume of air delivered by a compressor in M3 / minute. is compressor capacity.

Free Air Delivery; – Quantity of air in M3 / minute produced by. existing temperature and pressure. at the suction of compressor is free air delivered.

Swept Volume; – The swept volume is the volume of air displaced by the diameter of the piston in one full stroke. from BDC to TDC

Classes of Compressors

Positive displacement compressor

Compresses the volume of air and forces it to a smaller volume

- Rotary compressor

- Reciprocating

Centrifugal type of compressor

This type of compressor accelerates the air and. converts the energy into kinetic energy

- Centrifugal

- Axial

Reciprocating Compressor

In reciprocating type, compressor

- compressor sucks the air in the cylinder

- The piston compresses the air and expels to the discharge line.

- The valves fitted in the cylinder regulate the flow of air from the cylinder.

Types of reciprocating compressor

- Single-acting

- Double acting

Single acting

Single-acting compressor is with one discharge stroke in each revolution of the crankshaft.

Double acting

Double acting compressor is with two discharge strokes in every revolution of crankshaft.

1) Screw type

2) Reciprocating Type

3) Centrifugal Type

4) Rotary Type

5) Diaphragm Type

Use of Reciprocating Compressors.

1) Marine Engines

2) Industrial Diesel Engines

Air Compressor working principle

- A spring-loaded Non- return delivery valve operates.

- The compressed air flows through at constant pressure.

- The cycle completes the stroke.

- The differential pressure across the valve shuts the discharge valve.

- This process traps a small quantity of high-pressure air in the. clearance area between the piston and the cylinder head.

- On the induction stroke, the air in the clearance space expands.

How does a Marine compressor work?

A single crank single-acting Marine Air Compressor is the connection of- Low-pressure and high-pressure piston is tandem to a single crankpin low-pressure stage.

The external power of an Electric motor or a Diesel Engine rotates the crankshaft. Crankshaft gives drive to the piston.

In single-acting crank compressors.

The low-pressure and high-pressure pistons connects to two separate cranks. As the low-pressure piston moves down, the air sucks in through the air filter. And delivers the compressed air to the second stage through the intercooler.

During this cycle piston compresses the air in the second stage. Delievers high-pressure air to the aftercooler.

The compression process takes place during the upward and downward strokes.

As per the Arrangement, The low-pressure first-stage piston is at the top, and the high-pressure piston is at the bottom. Thus, as the piston moves up in the first stage, it compresses the air. Compressed air enters in the second stage.

The compressed air is once again pressurized in the second stage in the down stroke of the piston.

In the meantime the low-pressure side sucks. The fresh charge from the atmosphere through the filter. This process completes the cycle.

In the three-stage compressor type, the First stage sucks the air. Compresses the air and after the compression. Sends the air to intercooler for the cooling. From the IntercoolerIntercooler, the air eneters the second stage.

After compressing the air, compressed air gets in to 3rd stage

In the upward stroke of the piston, the piston compresses the air in the first and third stages. The air from the first stage enters into the second stage.

Advantage of Multistage compressors

- Power reduction in driving the compressor

- Enhanced mechanical balancing of the complete unit with uniform torque.

- Improved volumetric Efficiency

- Minimized losses due to leakages.

- Low working temperatures enable easy lubrication.

- Reduction in-cylinder weights.

- Due to low working temperature, could use low-cost material.

Compressor Efficiencies

- Volumetric Efficiency. Volumetric efficiency is the ratio of air discharged to the volume a displaced by piston.

- Isothermal Efficiency;- Is the ratio of isothermal power to the indicated power.

- Mechanical Efficiency- indicated power to the brake power ratio is the definition of Mechanical efficiency

Components of Marine Air Compressor

We will discuss about the major working parts of a reciprocating air compressors.

Safety devices on Air Compressor

Relief valve on HP and LP stage.

Intercooler bursting disc( water side)

After cooler fusing plug

Auto Moisture drain valve

Cooling water supply failure alarm

Low lubricating pressure alarm

Crankcase lube oil pump relief valve

Discharge air high temperature cut out alarm.

Starting procedure of a Marine Air Compressor

- Always keep the Marine Air Compressor unloading system in on position.

- Turn the supply of cooling water on and check the flow and inlet pressure of cooling water.

- Rotate the wheel drive belt by few turns for the freeness. This action is mandatory for the compressor starting after a prolonged period.

- Check the oil level and operate the force-feed lubricator for around 8 to 10 turns.

- Ensure the availability of lube oil to cylinders.

- Check the oil level in the sump and top up if needed.

- Position of the safety shut down switches in normal working condition.

- Drain the condensate from the intercooler and aftercooler.

- Ensure the V belt is tight as per norms.

- Open the stop valve for the air to flow to the air bottle/receiver.

- Press on the button from the control panel to start the compressor.

- Watch the oil pressure with the pressure gauge. stop the compressor immediately If the indicator is not showing the proper pressure.

- Check the lubricating oil flow from the lubrication pump.

- Put the compressor load after 5 minutes of satisfactory operation.

- Check the water flow to the cylinder and coolers.

- The inter-stage pressure should be within range.

- Check and rectify leakages in the system.

- The voltage at each terminal must be as per the specified levels.

- Check the discharge air temperature. The greatest permitted air outlet temperature is 75Deg C.

- Check and tighten the fasteners at regular intervals of operation.

- Listen to the abnormal noises and take immediate action. if any obnoxious noise is present.

Stopping procedure of a Marine Air Compressor

- Unload the compressor with the help of the installed control/ device

- Run the compressor at idle for 5minutes.

- Stop the compressor

- Close the cooling water supply

- Drain the condensate from the points.

- Isolate the power supply to the starter.

How to make a Marine Air Compressor more efficient?

- Supply the cool air to comressor for better efficiency.

- Clean the air filters at correct interval.

- Maitain the Compressor valves.

- The manometer instrument across the filter should be in good condition.

- Reduce the compressor low load operations.

- clean the inter coolers as per schedule or is the air temperature increases..

- Conduct the free air delivery test and compare with the compressor design data.

- Keep Option of Multistage compressor as far as possible.

- Regulate the delivery pressure.

- Maitain the closer range between load and unload.

The key points of the Marine Air Compressor efficiency

- Regulate the drain frequency.

- Check and take the action on logbook abnormal records.

- Carry out periodic leakage test.

- Install the solenoid valve to interlock and cutoff the machine if not in use.

- Maintain all the pneumatic tools with proper lubrication.

- Discourage the improper use of compressed air for cleaning the body and floor.

- Maintain the correct operating pressure of instruments to prevent waste of air.

- Replace the tools with tools operating on electricity.

- Try to use welded connections.

- Always use ball or gate valves.

General Problem of Marine Air Compressor on Ship

Pressure Test of Air Compressor

Carry out the hydraulic test on Cylinders, cylinder cover, Inter & After coolers

- Air Side: 1.5 x max. Working Pressure.

- Water Side: 4 bar or 1.5 x max. WP (whichever is greater)

Air Receiver

Each vessel will have two similar air receivers and a emergency bottle.

The total capacity of air receivers must be enough to meet the following need.

1) For 12 starts for the reversible engine

2) For 6 starts for the non-reversible engine, without refilling the receivers.

Mountings on Air Receiver

- Fusible Plug;- Each receiver will have a fusible plug at the bottom of the receiver.

Material of Fusible Plug- Bismuth 50%, Tin 30%, lead20%

Melting Point; – 104 Deg C

- Safety Valve;- Set pressure of safety valve will be 32 to 35 bar ( working pressure 30 bar).

- Compensating Ring;- This ring is mounted on a cut or machining hole to reduce the stresses.

- Manual or Automatic drain valve

- Pressure gauge

- Pressure switch.

Internal Surface coating;- an epoxy coating inside the receiver protects the receiver from corrosion, anti toxic or anti-oxidation.

Safety Device on Main Air Bottle

- Fusing Plug

- Pressure relief valve

- Low air pressure alarm

- Automatic moisture drain valve.

Reciprocating Compressors:: Operation and Maintenance

For anyone responsible for purchasing, servicing, or operating reciprocating compressors, this book discusses the theory of operation and explains how to install, troubleshoot, overhaul, and repair all types of compressors.

This broad comprehensive text offers practical details on how to purchase, service, operate, and maintain compressors used in any of the process industries, Marine etc

Our Best Picks on air Compressors

VIAIR 300P Air Compressor Kit

The VIAIR 300P Air Compressor Kit is a 12V DC portable tire inflator that is designed for use with off-road vehicles such as trucks, Jeeps, and SUVs. It has a maximum working pressure of 150 PSI and can provide a flow rate of 2.3 cubic feet per minute (CFM), which makes it suitable for inflating larger tires.

This air compressor kit comes with a range of accessories, including a 5-in-1 inflator/deflator with inline 100 PSI gauge, a 25-foot extension hose, and a heavy-duty battery clamp with a 40-amp inline fuse. The compressor itself features an easy-to-read pressure gauge and a built-in LED work light to help you inflate your tires in low-light conditions.

Overall, the VIAIR 300P Air Compressor Kit is a reliable and powerful tool that can help you keep your off-road vehicle’s tires inflated and ready for action.

California Air Tools 8010 Steel Tank Air Compressor

The California Air Tools 8010 Steel Tank Air Compressor is a portable and oil-free air compressor designed for various applications, such as home workshops, DIY projects, and small-scale professional jobs. It features an 8-gallon steel tank that can store a large amount of compressed air, allowing it to deliver consistent performance over extended periods of use. The compressor is powered by a 1.0-horsepower motor, which runs at a low RPM to reduce noise and increase the compressor’s overall lifespan. It has a maximum pressure of 120 PSI and a flow rate of 2.20 CFM at 90 PSI, making it suitable for inflating tires, powering air tools, and spraying paint.

It also has an easy-to-use control panel, a quick-connect air hose, and two pressure gauges for easy monitoring of performance. Overall, the California Air Tools 8010 Steel Tank Air Compressor is a versatile and reliable tool that is suitable for DIYers and small-scale professionals who need a portable and high-performance air compressor.

DEWALT Pancake Air Compressor

The DEWALT Pancake Air Compressor is a portable and compact air compressor that features a 6-gallon pancake-style tank, which provides ample power for most jobs. It has a maximum pressure of 165 PSI, which allows it to deliver consistent performance even during prolonged use.

This air compressor is powered by a 0.8 horsepower motor, which operates at a relatively low noise level of 75.5 dB, making it suitable for use in indoor environments. It delivers 2.6 CFM at 90 PSI, which is enough power to handle a variety of applications, including inflation, nailing, stapling, and airbrushing.

The DEWALT Pancake Air Compressor also features two universal couplers that support two users at the same time, and a high-flow regulator that helps to increase the compressor’s overall efficiency.

Overall, the DEWALT Pancake Air Compressor is a reliable and versatile tool that is suitable for DIYers and professionals who require a portable and powerful air compressor for a variety of tasks.

Kensun AC/DC Power Supply Portable Air Compressor Pump

The Kensun AC/DC Power Supply Portable Air Compressor Pump is a versatile and compact air compressor that is designed for use in both home and car settings. It features an analog display that can reach up to 100 PSI, making it suitable for inflating a wide range of items, including car and truck tires, bicycles, and sports balls.

One of the standout features of this air compressor is its dual power supply. It can be powered by either a 110V AC wall socket or a 12V DC car socket, which makes it easy to use in any location. It also comes with a variety of adaptors, including a needle valve adaptor for inflating sports balls, a Presta valve adaptor for bicycles, and a nozzle adaptor for inflating other items.

The Kensun AC/DC Power Supply Portable Air Compressor Pump is also compact and lightweight, which makes it easy to store and transport. It features a built-in handle for easy carrying and an 11.5-foot power cord that allows for easy access to the tires on all sides of a vehicle.

Overall, the Kensun AC/DC Power Supply Portable Air Compressor Pump is a versatile and reliable tool that is ideal for anyone who needs a portable and convenient air compressor for inflating a wide range of items at home or on the go.

Blog Conclusion

In conclusion, a marine air compressor is a crucial tool for anyone who owns a boat or yacht. It allows for the inflation of life jackets, fenders, and other important safety equipment, as well as powering air tools and other devices on board.

When choosing a marine air compressor, it’s important to consider factors such as power output, tank size, and noise level. A compressor with a high CFM rating and large tank size will provide ample power and allow for longer periods of use, while a quieter compressor will minimize noise pollution on board.

Additionally, it’s important to consider the type of power source required for the compressor, such as AC or DC power, and whether it comes with features such as an automatic shut-off or moisture trap to ensure safe and efficient operation.

Overall, investing in a quality marine air compressor is a wise choice for any boat or yacht owner, as it will ensure the safety and comfort of all on board, while also providing the power necessary to complete a wide range of tasks and projects.