Table of Contents

How to Clean Fuel Injectors

Embarking on the journey to maintain your marine diesel engine at peak performance, one critical task stands above the rest: keeping your fuel injectors spotless. These small components pack a mighty punch, pivotal in your engine’s power and efficiency. If you begin to notice that your boat isn’t sailing as smoothly or the engine isn’t quite roaring with its usual vigor, it may be a sign that your fuel injectors are calling out for a clean.

Cleaning fuel injectors is an essential skill for any boat owner. It’s not a complex mystery reserved for diesel mechanics; with the proper instructions and tools, even novices can ensure their marine engine remains in shipshape. Doing so not only improves fuel efficiency, saving you money on diesel, but also prevents the high costs associated with engine repairs. Plus, it’s a win for the environment as clean injectors lead to more pristine seas with less harmful emissions.

We’re delving deeply into the systematic procedure for cleaning the fuel injectors in your marine diesel engine in this blog post. This tutorial will make cleaning marine engines easy for you, no matter how much experience you have with them. With gasoline injectors as clean as the ocean breeze, your engine will operate at peak efficiency as you prepare to sail on a smoother voyage. Keep reading as we chart the course for optimal engine performance and longevity with our comprehensive cleaning guide.

Signs of Dirty Fuel Injectors

When your diesel engine starts acting up, it could be shouting for a clean-up of its fuel injectors. Here are some tell-tale signs that your fuel injectors might be dirty:

- Decreased Engine Power: If your engine isn’t as strong as it used to be, dirty fuel injectors could be failing to deliver the fuel your engine needs.

- Reduced Fuel Efficiency: Are you visiting the fuel pump more often? Dirty injectors could make your engine guzzle more fuel by burning it inefficiently.

- Rough Idling: Does your engine sound rough and uneven when waiting at a light? This could be a symptom of injectors not providing a steady fuel flow.

- Increased Emissions: More smoke than usual could mean fuel isn’t burning entirely because your injectors are clogged, pumping out more pollutants.

- Engine Misfires: If your engine is hesitating or outright misfiring, it might need to get the quick, precise bursts of fuel it needs from the injectors.

- Reduced Acceleration: When your boat is dragging and not picking up speed, dirty fuel injectors could slow you down.

If you’re noticing any of these issues, it’s wise to get your fuel injectors checked and cleaned promptly. Keeping them clean not only boosts your engine’s performance but also saves you from expensive repairs.

Identifying Symptoms for Preventing Engine Damage

Catch the warning signs of dirty fuel injectors early, and you could spare your diesel engine many problems. It’s vital to recognize these clues quickly to clean the injectors and keep your engine running smoothly. If you shrug them off, you might end up with an engine that misfires, wastes fuel, and creates extra pollution.

Stay alert to these hints that your injectors are dirty, and you can keep your engine in good shape. Ignoring them might lead to a hefty repair bill, or worse, you might need to replace your engine entirely. So, to avoid trouble, make it a habit to inspect and clean your injectors regularly.

Get to know the tell-tale signs of injector dirtiness. Once you spot any, act fast to fix the issue. This smart move will help you prevent severe engine damage and save a chunk of change on future repairs.

Tools and Materials Needed for Cleaning Diesel Engine Fuel Injectors

Special tools and instruments will be required for the proper cleaning of the fuel injectors:

- Fuel Injector Cleaning Kit: This kit has a canister of cleaning solution, hoses, and adapters to connect to the fuel injectors.

- Safety Equipment: Always wear safety gloves and glasses. They will protect your hands and eyes from the cleaning fluids and dirt or debris.

- Cleaning Solution: You’ll use this specialized cleaner to dissolve and wash away the gunk from the fuel injectors.

- Compressed Air: You’ll need this to blow away any loose debris after you’ve applied the cleaning solution.

- Rags or Shop Towels: Keep these handy to wipe up spills and any excess cleaner.

- Fuel System Cleaner: After you’ve cleaned the injectors, add this to your fuel system for an extra thorough clean.

Make sure you use the right tools and materials for cleaning your fuel injectors. The correct items will help you clean effectively and avoid damage. Always follow the manufacturer’s instructions and choose the products they recommend.

Step-by-Step Guide on How to Clean Fuel Injectors

Cleaning fuel injectors on your marine diesel engine is straightforward. Here’s how to do it:

- Gather Your Cleaning Gear: Before you start, collect all the necessary items. This includes a fuel injector cleaning kit, safety gloves, goggles, a cleaner for fuel injectors, compressed air, rags, and a cleaning agent for the entire fuel system.

- Suit Up for Safety: It’s essential to protect yourself. Put on your gloves and goggles to keep the cleaning agents and any small debris off your skin and out of your eyes.

- Reduce Fuel Pressure: Check the engine’s manual to find a safe way to reduce fuel pressure. This is a crucial step to prevent fuel spraying when you detach the injectors.

- Detach the Injectors: Shut off the engine’s fuel system and let the pressure in the fuel lines drop. Your engine’s manual will guide you through this process. Then, you can remove the injectors.

- Remove the Injectors: If necessary, remove the injectors from the engine. Handle them gently to avoid causing any harm.

- Hook Up the Injectors to the Cleaning Kit: Follow the directions provided with your cleaning kit to connect the injectors properly. Make sure the connections are secure to prevent leaks.

- Flush the Injectors: Push the cleaning fluid through the injectors to remove any internal grime or deposits. Always do this in a well-ventilated area.

- Clean the Injectors Externally: Take the opportunity to clean the outside of the injectors with a rag and a suitable cleaning agent.

- Reinstall the Injectors: Once clean, place the injectors back into the engine. Ensure they’re correctly positioned, and all the connections are secure.

- Purify the Fuel System: Add a cleaning solution to the fuel system to help cleanse the entire circuit.

- Run the Engine: Power up the engine to ensure it operates smoothly. Pay attention to any strange noises or idling that might indicate an issue.

Be sure to refer to the specific manual for your marine diesel engine for detailed instructions. Clean your fuel injectors in a safe, airy space. Regular maintenance, like cleaning your fuel injectors, will keep your marine engine running effectively and prolong its life.

Simple Steps to Clean Fuel Injectors with a Cleaning Solution

- Prepare the Cleaning Solution: First, get your fuel injector cleaning kit ready. Pour the proper cleaning solution into the kit, using a funnel to prevent spills.

- Attach the Kit to Injectors: Next, connect the kit’s hoses and adapters to your fuel injectors. Follow the instructions that came with your equipment. Ensure all connections are snug to avoid leaks.

- Run Your Engine: Now, start your engine and keep it running for the duration specified in the kit’s instructions. The solution will circulate through the injectors, cleaning them as it move through.

- Shut Down Engine: After the required time, turn off the engine. Then, carefully disconnect the cleaning kit from the injectors. Remove any protective covers you put on the fuel lines and reconnect everything – the fuel pump, the fuel filter, and the fuel rail.

- Test Your Engine: Finally, start your engine again to test it. You should notice it running smoother, responding better when accelerating, and using less fuel.

Straightforward Guide to Testing and Calibrating Fuel Injectors

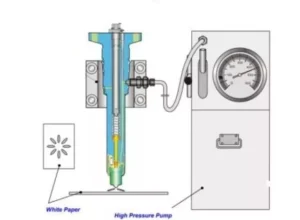

- Remove Injectors: Start by taking the fuel injectors out of the engine. Attach them to the injector testing machine. Please make sure they’re clean and have no debris on them.

- Inspect Visually: Now, look at each injector closely. You’re checking for any cracks, rust, or other problems that could mess with how well the injector works.

- Check Spray Pattern: Turn on the testing machine to see the spray pattern for each injector. It should look like a fine mist without big drops or uneven sprays. If it doesn’t, you might need to clean or replace that injector.

- Measure Flow Rate: The testing machine can also measure how much fuel flows through the injectors. It should match what the engine manufacturer says is right. If it’s too little or too much, you should clean the injector or adjust it.

- Calibrate Injectors: If the flow rate isn’t correct, use the machine to set it properly. Follow the instructions from the injector’s maker, using the engine’s manual as a guide to get the proper flow.

- Put Injectors Back: Once you’ve made sure the injectors are working well and are set right, put them back in the engine. Make sure to install them exactly as the manual says.

- Test the Engine: Finally, start the engine and watch how it runs. It should idle smoothly and not misfire. If it does something strange, you should run a diagnostic to find and fix the problem.

Simple Steps to Reinstall Fuel Injectors

- Replace O-rings: Before you put the injectors back in, fit new O-rings on them. These rings must be the right size for your engine to prevent leaks.

- Lubricate O-rings: Put a bit of petroleum jelly or a silicone-based lubricant on the O-rings. This helps them slide into place without tearing.

- Insert Injectors: Carefully place each injector back into its slot on the fuel rail and the intake manifold. Make sure each one is straight and sits snugly to avoid leaks.

- Tighten Injector Bolts: Use a torque wrench to tighten the injectors’ bolts. Check the repair manual for the exact tightness needed. Keep them tight enough, or you might break something.

- Reconnect Fuel Lines: Put the fuel lines back on the fuel pump, filter, and rail. Use the right tool to hook them up tightly to the injectors.

- Reconnect Electrical Connectors: Plug the electrical wires back into the injectors. They should click in place and be secure.

- Test the Engine: Turn on the engine to check your work. Look for leaks or odd sounds. Keep an eye on how the engine runs for a bit to make sure the injectors are doing their job right.

Checking Your Marine Diesel Engine After Fuel Injector Service

- Start the Engine: Fire up the engine and let it idle. Keep an eye on how smoothly it’s running, and be alert for any unusual sounds or vibrations that weren’t there before.

- Test Response: Increase the throttle and observe the engine’s response. Hesitation or a bumpy increase in speed may indicate the injectors need to be entirely right.

- Examine the Exhaust: Check out the exhaust for any smoke. Dark smoke could mean too much fuel is being burned. White smoke might signal a leak of coolant or oil into the combustion chamber.

- Diagnostic Check: Connect a marine engine diagnostic tool. This gadget will check for any error messages or issues post-cleaning. It’s a smart way to catch anything missed.

- Operational Test: Run the engine under normal operating conditions. This isn’t just about speed but also how the engine handles and reacts. Anything out of the ordinary could point to a problem beyond the injectors.

Always go over these checks thoroughly. If you find something off, it could be related to the injectors or another aspect of the engine’s function.

Simple Steps to Keep Marine Diesel Engine Fuel Injectors Clean

- Choose Top-Notch Fuel: Always fill up high-grade diesel with the proper additives. This helps stop gunk from building up in your engine’s fuel system.

- Swap Out Fuel Filters on Time: Stick to the maker’s schedule for changing fuel filters. This keeps dirt and grime away from your fuel injectors.

- Use Cleaners for Your Fuel System: Now and then, pour a cleaner made for fuel systems into your fuel tank. It cleans out any crud that’s starting to gather.

- Run Your Engine Right: If you can, skip short runs where the engine doesn’t get hot enough. Getting to the proper temperature can prevent the incomplete burning of fuel, which leaves behind deposits.

- Watch How You Drive: Try to drive smoothly. Jerky and fast driving can make the engine pump in too much fuel too quickly, which can make more deposits.

- Stick to a Maintenance Routine: Keep your engine in top shape with regular oil changes, air filter swaps, and coolant changes. This helps to fend off deposit buildup in your fuel system.

MOSTPLUS Flow Matched Fuel Injectors

MOSTPLUS Flow Matched Fuel Injectors are precisely calibrated fuel injectors designed to ensure that each injector delivers the same amount of fuel to the engine. These fuel injectors are made from high-quality materials and are designed to meet or exceed OEM specifications. They are available in a range of flow rates and are compatible with various types of vehicles. Installing MOSTPLUS Flow Matched Fuel Injectors can improve engine performance and efficiency by ensuring that the engine is receiving the correct amount of fuel.

Conclusion on How to Clean Fuel Injectors

In conclusion, keeping your fuel injectors clean is crucial for maintaining your marine diesel engine’s performance. Start by preparing with the right tools and safety equipment. Safely lower the fuel pressure as directed by the engine’s manual to prevent accidental fuel spray. Carefully remove the injectors, taking care to avoid any damage. Use your cleaning kit to connect the injectors securely and run the cleaning solution through them in a well-ventilated area.

After cleaning, wipe down the injectors and put them back into place, ensuring everything is properly tightened. Finally, add a fuel system cleaner to the tank and give your engine a test run, listening for any irregularities and ensuring it idles smoothly. Regular cleaning of the fuel injectors can significantly extend the life and efficiency of your marine diesel engine.

FAQ on How to Clean Fuel Injectors

Q: How often should I clean my fuel injectors?

A: Clean your fuel injectors every 15,000 to 30,000 miles to maintain optimal engine performance.

Q: What do I need to clean my fuel injectors?

A: You need a cleaning kit, safety gear, solution, and compressed air to clean your fuel injectors.

Q: Can I clean fuel injectors myself?

A: Yes, you can clean fuel injectors yourself by following the engine’s manual and using a proper injector cleaning kit.

Q: How do I know if my fuel injectors need cleaning?

A: If your engine misfires, idles roughly, or you notice a drop in fuel efficiency, it might be time to clean your fuel injectors.

Read our related posts:-

Fuel injection system of diesel engine | 22-23 The best-updated tutorial on

Fuel Injector and How it Works | 23-24 The best tutorial for Engnrs