Valve Seat ring and valve spindle re-conditioning

Table of Contents

Valve Seat reconditioning of Cylinder Head Marine Diesel Engine

Carry out the reconditioning of the valve grinding machine.

Valve seat re-conditioning procedure

- Feed angle for the grinding of the seating surface will be as per the following feed angle..

- Continue the grinding till the achievement of a clean and uniform surface.

- To obtain the best surface finish, carry out the grinding with feed-in opposite direction, i.e., inside to outward.

- Carry out the grinding till recess R is visible. If there is no recess than Reject the seat.

Valve Seat Surface checking after reconditioning

Check the contact of both the seating surface of the valve seat ring and valve spindle seat on completion of the grinding process of the valve seat ring.

- Apply the blue-compound thin layer on the valve spindle seating surface.

- Insert valve into the valve guide of the cylinder head.

- Rotate the valve to and fro by 1/3 turn with light pressure.

- Pull out the valve and inspect the contact pattern on the valve seat ring.

Observation:- The contact pattern/ mark should start from outer diameter towards inward radially, and the width of the contact area should be 2-3 mm continuously all over the circumference.

Valve Spindle re-conditioning Cylinder Head Marine Diesel Engine

Carry out the reconditioning of valve spindles in the lathe machine and mount the special grinding machine in the tool post of the lathe machine.

Procedure for Valve spindle re-conditioning.

- Grind the seating surface with the feed angle illustrated in the above fig.

- Continue the grinding till the achievement of the clean and uniform surface of the valve seat lid.

- Final check is to measure the Height ‘H’.

- The achieved H has to be as per the description of the below image.

Check for the valve assembly

Valve Spindle height measurement

Check the Height between the top end of the valve spindle and the upper edge of the cylinder head.

Valve Guide Replacement (Cylinder head forDiesel Engines)

It is mandatory to replace the valve guide if the clearance has increased more than the specified limits by the equipment manufacturer.

Valve Guide Removal Procedure for Cylinder Head Marine Diesel Engine

Blow out the valve guide from the bottom of the cylinder head using a special mandrel having shoulders. These shoulders fit at the collar of the valve guide.

- Properly clean the valve guide with compressed air. Inspect for any abnormal marks at the surface of the bore, which might restrict the proper fitment of the new valve guide

- Cool the new valve guide to -70 deg C with dry ice/dry nitrogen.

- After inserting the new valve guide, tap slightly at collar with mandrel and hammer to ensure even seating at the cylinder head.

- Discard old O ring and replace with new ring..

Safety Valve Maintenance (Cylinder head for Marine Engines)

Clean the safety valve thoroughly during standstill and at Major maintenance of the engine. It is a bad practice to increase the spring tension to arrest the leak.

The opening pressure setting is marked/ stamped on the cap nut.

Safety valve dismantling procedure

- Remove the safety valve from the cylinder head.

- Hold the valve in the table vice.

- Open the cap nut (1) by screwing it out.

- Remove the spring (3)

- Remove the valve (4).

- Remove the valve cone(6)

- Inspect the valve after careful cleaning. Carry out the reconditioning of the valve if necessary.

Safety valve assembly procedure of Cylinder Head Marine Diesel Engine

- Smear the valve housing threads with copaslip or some other available substitute.

- Assemble the safety valve in the reverse sequence of operations 1 to7.

Safety Valve Test

Carry out the leak test and opening pressure test on completion of each overhaul.

- Connect the safety valve to the Fuel injection test pump with the help of a high-pressure fuel injection pipe.

- Keep venting the system by pumping till air-free bubble emerges out from port (7) in the valve body (2).

Safety Valve Leakage Test

- Slowly raise the pressure to 135 bars.

- Check the pressure drop for 01 minutes. Pressure shouldn’t fall below 135 bars within the above period.

- If the pressure is constant for 01 minutes, then continue raising the pressure to opening pressure.

- If the pressure falls below 135 in 01 minutes, scrap/ recondition the valve by lapping the procedure.

- Raise the pressure to opening pressure

- If the opening of the valve is correct at opening pressure, then finish with the test procedure.

- If the valve is not opening at the correct specified pressure, then carry out the re-adjustment of the valve.

Opening Pressure Adjustment

- Raise the pressure to opening pressure.

- Adjust the opening pressure by the cap nut (1) to the correct lifting pressure.

- Drill a hole to fix the safety pin (5).

Mounting back the safety valve of Cylinder Head Marine Diesel Engine

- Smear the threads on valve housing with copaslip.

- re-assemble the safety valve in the cylinder head.

Indicating Valve

Uses of indicating valve are as under

- For blowing through the engine before starting

- For the measurement, Pmax and taking indicator diagrams.

- During engine crankshaft, easy shaft barring/Turning.

Indicating Valve Maintenance Cylinder Head Marine Diesel Engine

In normal working conditions, the valve doesn’t require much maintenance except inspection during the cylinder head maintenance/ overhaul.

Indicating Valve Inspection

- Dismantle the indicating valve

- Visually inspect the condition of the valve cone and seat for any burning through.

- Replace the entire valve if the turning of the valve seat in the housing is persisting.

- Thoroughly clean and lubricate all parts of the valve before fitting back.

- Ensure that the valve spindle is in the fully open position during fitting back to prevent seat damage.

Injector Sleeve Replacement

Fuel Injector Sleeve removal

- Take out the snap ring using two screwdrivers

- Drive out the sleeve from the bore with the help of a hammer and brass mandrel.

Cylinder head bore for sleeve inspection and fitment of the sleeve.

- Clean and inspect the bore thoroughly for any burs or high surface, restricting the sleeve installation. Sooth the surface lightly with soft emery paper.

- Smear the sealing ring surface with lubricating oil/grease.

- Cool the sleeve in dry ice up to-15 Deg C.

- Insert a new sealing ring on the sleeve.

- Apply Loctite 572 at the sealing surface of the sleeve.

- Install the sleeve in the bore.

- Fit the snap/ lock ring.

Valve Seat Ring Replacement (Cylinder head for Marine Engines)

Extraction of Valve seat Ring

When reconditioning possibilities don’t exist due to the exceeding dimensions, reject the valve seat ring.

Extract the Valve seat ring with a special extractor tool consisting of the following tools.

Valve Seat Extracting Method (Cylinder Head Marine Diesel Engines)

- Vertically place the guide disc (5) with the help of guide pin (7) through the valve set ring. Lift the guide disc with a guide pin (5) until the guide disc is guided with the valve seat ring.

- Fit the guide (disc) (3) for it to contact against the lower part of the cylinder head. Install the hydraulic jack with the guide disc (4) and hexagon collar nut (2). Hydraulic jack is the same as for the use of bearing removal of main bearing caps. Hydraulic jack is the same as for the use of bearing removal of main bearing caps.

- Pump up the hydraulic pressure till the set gets extraction up to 6mm. Re-adjust the extraction tool after Releasing the pressure. Pump up again and extract the complete valve seat ring.

Fitting a new Valve Seat Ring (Cylinder head for Marine Engines)

- Clean the bore properly and inspect for any marks that will restrict the new valve seat fitting.

- Tools for the valve seat ring fitment as per the illustration in the following fig.

- Cool down the valve seat ring to a minimum of -25 deg C for the easy insertion of the valve seat ring. Cooling below this temperature will cause damage to the O ring.

- Insert the O ring in the valve seat ring groove with a coating of oil/Loctite before the fitment.

- Position the valve seat ring in the bore with the handle having stud and washer.

- Knock at the handle and tighten the nut (4). Knock it down slowly till the seat bears against the cylinder head and a solid sound of a hammer.

- Center the valve seat ring by grinding it with a valve seat grinding machine.

Cylinder Head Mounting (Cylinder Head Marine Diesel Engines)

- Inspect the cylinder head and cylinder liner top for the cleanliness of any damage.

- Replace the O ring in cooling water passage.

- Smear the O ring with oil.

- Inspect the contact surfaces of the nuts and threads for cleanliness and damages.

- Place the cylinder head on the top of the cylinder liner with the help of cylinder head lifting tool.

- Check the nuts for their easiness on the threads.

- Apply molycot on the matting and threaded part.

- Put the nuts on and tight with Tommy bar.

- Tighten and loosen the new nut to relieve from their deformation

- Carry out the tappet clearance adjustment.

- Install back all the pipelines and supporting frames.

- Check the leakage test of Lube oil and cooling water.

- Fit all the covers removed before dismantling.

Cylinder Head cooling water spaces Inspection (Cylinder Head Marine Diesel Engines)

Inspect cooling water inlet and outlet as per the below fig.

- De-scale the complete cylinder head in case of scale formation.

- Inspect the chocking by pouring the water inlet and flow out from the inlet of the cylinder head.

- Use the wire brush for cleaning purposes and carry out proper flushing.

Balancing yoke adjustment

Yoke presses the inlet valve and exhaust valves simultaneously. Balance the yoke precisely for the even and smooth operation of Valves.

Improper adjustment of clearances on yoke will cause unbalance force on the yoke, and the unbalanced yoke would cause damages on yoke and guide pin.

A broken yoke or guide will cause repeated unbalance movement of valve spindles leading to failure of valve spindles and serious damage to the engine.

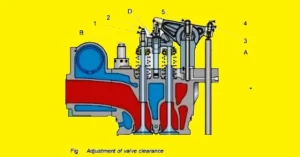

Procedure for adjustment of Yoke Clearance

- Bring the valves in full close position by turning the crankshaft.

- Check the pushrods are without spring force and free moment and clearance.

- Loosen the locking nuts (1, 3) and carry out the adjustment with adjusting screws (2, 4).

- Press the yoke on the non-adjustment side to contact valve stem (A) firmly as per the below fig.

- During the contact, (A) rotate the adjusting screw till the adjusting screw establishes the connection at valve stem B.

The easiest method is to place the dial gauge on the valve rotator and noticing the needle movement.

- Press the (A) side and measure the clearance of B by a feeler gauge.

- Same way compress the side “B” of the yoke and carry out the adjustment of Valve clearance “A” with the use of feeler gauge.

- Keep adjusting the screw till there is no difference in clearances, in turn pressing the opposite side of the yoke.

- Repeat the adjustments till both clearances are of the same reading. On completion of the adjustment, tighten the locknut (1) holding the adjusting screw (2) for not turning while tightening. Apply the correct tightening torque and apply molycote on the nuts.

Repeating is necessary to ensure the non-tilting of the yoke on one side.

Re-confirm the clearances on completion of tightening the lock screws.